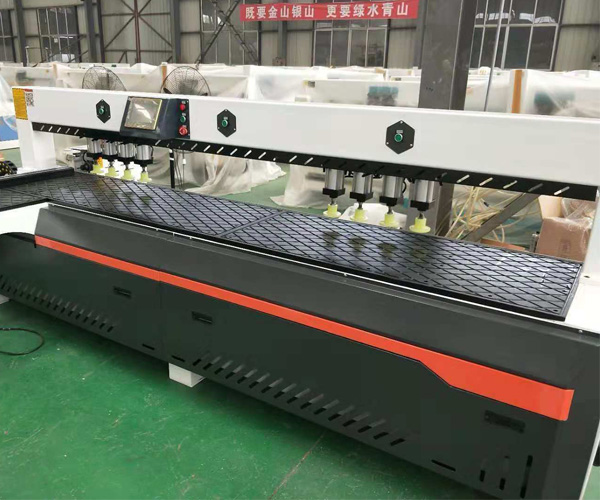

The operation process of the side hole machine is as follows:

1. Connect the power and check if all components of the machine are functioning properly.

2. Place the fixed plate to be processed on the workbench, confirm that it is correct, open the tool clamp cover, loosen the front and rear adjustment screws of the ejector cylinder, and remove the cover wrench (remember to keep it safe). Set the required parameter values (such as drilling depth, rotation speed, etc.) on the computer screen. Then switch the gear on the monitor to "manual" mode, push and hold the dual handle lever downwards until pressure is felt, and then release it for a buckle test to test its accuracy. At the same time, adjust the gap between the jaws and the distance between the mold, rocker arm, and base according to the sample to achieve the best position and good repeatability. If replacement of cutting blades or other maintenance work is required, the main power must be cut off before implementation. (Note: Please do not repair without the protection of technical personnel.) 3. For different workpiece materials, appropriate cutting angles should be selected to improve work efficiency and quality requirements; At the same time, the process method and scope of application should be determined based on the standard samples provided by the customer to ensure that the accuracy of the product meets the customer's expected level. 4. Operators must undergo training and assessment before they can work independently. It is strictly prohibited to start without a license! Throughout the process, safety precautions should be taken as the main focus to ensure that personal equipment is not damaged.

5. After use, turn off the relevant switches, organize the processing program files, and clean the machine tool to maintain a clean and tidy working environment.

6. Regularly inspect the various functions of the side air compressor and record and analyze them to promptly identify and solve problems, ensuring the normal operation of the equipment and improving production efficiency while safeguarding the safety of personnel's lives and property.

Before starting batch drilling, it is necessary to double check the quantity, model, specifications, and other technical conditions of the products again. If any of them are missing, work will not be started to avoid unnecessary trouble or even major accidents! The above is a detailed introduction on how to use it correctly. I hope it will be helpful to you!. The side profile produced by each manufacturer may vary slightly. Please refer to the manufacturer's user manual and instruction manual for specific details.

- Introduction to Side Hole Machine

- How to customize the edge inspection vibration knife integrated machine

- Common knowledge of side hole machine

- General instructions for pressurized drilling machine

- Introduction to Side Hole Machine

- Operation process of advertising engraving machine

- Precautions for cleaning advertising engraving machine